- Visibility 332 Views

- Downloads 29 Downloads

- Permissions

- DOI 10.18231/j.aprd.2025.011

-

CrossMark

- Citation

Natural alternative for denture polishing - Eggshell powder

Abstract

Introduction: Every dental material used in the oral cavity requires an effective finishing and polishing to ensure an acceptable oral health. Though dental pumice powder achieves a smooth and polished surface on acrylic resin, it still has its own limitations challenging to find a better alternative like commercially available Eggshell powder which provides the similar surface polish.

Aims & Objectives: The aim of this in vitro study was to compare the abrasive property of commercially available eggshell powder in reducing the surface roughness of denture base resins with that of the abrasive property of Dental Pumice Powder.

Material and Methods: Thirty poly methyl methacrylate (PMMA) specimens were fabricated and divided into two groups after standardised finishing. Group-P containing 15 PMMA Specimens were polished using commercially available Dental Pumice powder. Group-E contains 15 PMMA Specimens were polished using commercially available Eggshell powder. The average surface roughness (Ra) after polishing was measured with a surface roughness tester. T test was used to analyse and compare the Ra values.

Results: The p-value obtained from the t-test was 8.87608E-07 (0.000000887608), which is significantly lower than the conventional alpha level of 0.05. This result indicates a statistically significant difference in surface roughness between the two groups which used different polishing agents.

Conclusions: With in the limitations of the study, it was noted that PMMA specimens polished with dental pumice powder showed significantly lower surface roughness than those polished with eggshell powder. However, eggshell powder's comparable performance highlights its potential as a natural, eco-friendly alternative. This necessitates further studies on optimising its composition, such as reducing particle size or adding surfactants to enhance its polishing efficiency for dental applications.

Introduction

Acrylic denture base resin made of Polymethyl methacrylate (PMMA) is a widely used material in removable prosthodontics due to its favourable properties such as ease of processing, aesthetic appeal, and biocompatibility. In the field of prosthodontics, achieving a smooth and polished surface on acrylic denture base resins is essential for patient comfort, aesthetics, and reducing plaque accumulation. Surface roughness is an important parameter as it affects the retention of bacterial plaque, staining, and subsequently adversely impacts oral health.[1], [2] Surface roughness of denture bases can significantly influence the retention of biofilm and plaque, potentially leading to oral infections such as denture stomatitis. Tupinamba et al. [3] believe that correct polishing is essential in preventing bacterial retention and plaque build.

Pumice is a volcanic-origin abrasive widely used commercially available polishing agent in the field of dentistry especially in polishing the acrylic resins. Due to its effectiveness in reducing surface irregularities and achieving a smooth, lustrous finish, pumice has been a preferred choice for polishing acrylic materials. Its porous, lightweight structure makes it highly efficient at removing fine surface layers, ensuring a polished outcome without significantly altering the material's underlying structure.

In prosthodontics applications, pumice is generally available in various particle sizes, typically ranging from 100 to 300 microns, to allow for different levels of abrasion depending on the specific polishing requirements. [4] Coarser grades are used for initial surface reduction, while finer grades are often applied in the final polishing stages to achieve a smoother finish. This gradation enables clinicians to control the abrasion level, making pumice highly versatile for denture polishing.

However, pumice also has some limitations, such as potential dust generation and the need for repeated application to achieve a consistent finish. Additionally, pumice is not biodegradable and requires sourcing from specific geological locations, which can raise sustainability concerns. In light of these issues, we are investigating alternative materials like eggshell powder, which could offer similar or improved results, represents a promising step toward more eco-friendly, accessible, and cost-effective dental materials in clinical practice.

Eggshell powder, predominantly composed of calcium carbonate, has gained attention as a potential substitute for traditional abrasives like pumice in various polishing applications. Several studies.[5], [6], [7] have also reported that the calcium of eggshells is similar to that of bone and teeth, thereby supporting its use as an abrasive cleaner in toothpastes to remove dental plaque. Brandy-Garnys,[3] further revealed that eggshells are being used in the manufacture of abrasive paper, abrading wheels, bands and disks, and cosmetics. Onwubu et al,[8], [9] recently showed that eggshell powder with particle sizes ranging from 15 to 0.3µm may be employed as a substitute for pumice in reducing the surface roughness of PMMA base resin below the 0.2µm of threshold limit value. Its natural composition and fine particle structure offer an abrasive quality that, when appropriately processed, could achieve similar results to pumice. Studies have demonstrated that calcium carbonate-based powders can effectively reduce surface roughness in dental materials, providing an alternative polishing method.

By acting as a bio-based abrasive, eggshell powder aligns with green dentistry goals, providing a sustainable solution without compromising the surface quality of denture base materials. Further comparative studies, like this one, are essential to validate its efficacy fully and determine whether eggshell powder can reliably replicate or enhance the results achieved with pumice in clinical practice.

The aim of this in vitro experiment was to compare the abrasive efficiency of pumice with that of the commercially available eggshell powder and analyse the possibility of using dried eggshell powder as an easily available natural substitute for pumice

Materials and Methods

Pumice powder

Pumice (Samit- Fine Grade) was acquired from a local outlet. ([Figure 1]) This commercially available pumice was chosen due to its widespread use in dental polishing applications and its suitability as a comparative standard for evaluating the abrasive efficiency of eggshell powder.

Eggshell powder

Commercially available Eggshell powder ([Figure 2]) was purchased from Pioneer Agro, Coimbatore, with a particle size of 300 microns.

Preparation of polymethyl methacrylate (PMMA) specimens

To prepare the acrylic samples of specific dimension of 15 × 15 × 3 mm[9] dies were fabricated using 3D printing technology to achieve precision. ([Figure 3]) A total of 30 rectangular heat-polymerized acrylic resin specimens, each measuring 15 × 15 × 3 mm, were to be fabricated using a heat cure resin (DPI heat cure) following the manufacturer’s specified polymerization instructions. ([Figure 4])

A total of 30 (15 × 15 × 3 mm) heat-polymerized acrylic resin specimens were fabricated using the prepared Dies. ([Figure 5]) The specimens were carefully trimmed to size using a tungsten carbide bur (Cross-cut, coarse – ISO no. 500104237065; Bredent (GmbH & Co KG) operating at a high speed of 18,000 rpm, ensuring consistency in dimensions and initial surface texture. ([Figure 6])

Following trimming, all specimens were finished using abrasive paper (3M Sandpaper of 1000-600-250-100 sizes) to achieve a standardized baseline surface finish prior to the polishing procedure. This step ensured that each specimen had a comparable initial surface roughness, providing a consistent starting point for the comparative polishing analysis.

Polishing of the polymethyl methacrylate specimens

The specimens were then divided into two groups, each containing 15 PMMA blocks, to evaluate the effectiveness of pumice and eggshell powder as polishing agents:

Group P (Pumice): Fifteen specimens were polished using Dental pumice powder.

Group E (Eggshell Powder): Fifteen specimens were polished using Eggshell powder.

Polishing procedure

Dental prostheses are traditionally hand-polished in the dental laboratory by using a lathe machine and pumice as the abrasive material.[10] For each group, a consistent slurry was prepared by mixing 30 grams of powder (either pumice or eggshell) with 5 mL of water to achieve a uniform consistency. This slurry was used to polish the PMMA specimens, providing controlled and reproducible abrasive contact.

The polishing process was carried out using a rotary polishing device set to 1,500 revolutions per minute (rpm), with each specimen polished for a standardized duration of 2 minutes. During polishing, the slurry was continuously applied to maintain even coverage and abrasive action.

Upon completion of the polishing procedure, all specimens were thoroughly rinsed with distilled water to remove residual abrasive particles and then air-dried. ([Figure 7])

The polished samples in both Group-P and Group-E were analysed for Ra-Surface roughness using portable surface roughness tester {TESA rugosurf10}. ([Figure 8]) The obtained Ra valves were statistically analysed using T test.

Results

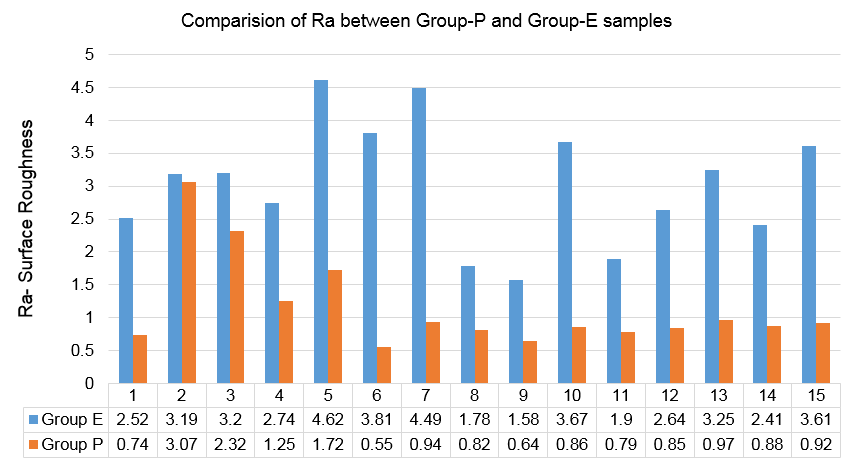

The surface roughness (Ra) values obtained after polishing with pumice and dried eggshell powder were measured and analysed to compare the efficacy of each abrasive in producing a smooth surface on polymethyl methacrylate (PMMA) specimens.([Figure 9])

Group P (Pumice): The specimens polished with pumice powder showed an average surface roughness (Ra) of 1.136667µm.

Group E (Eggshell Powder): The specimens polished with eggshell powder had an average surface roughness (Ra) of 3.027333 µm.

A t-test was conducted to evaluate the statistical significance of the difference between the two groups. The resulting p-value was 0.000000887608 (p < 0.05), indicating a statistically significant difference between the surface roughness values of specimens polished with pumice and those polished with eggshell powder.

Interpretation

The significantly lower Ra values in Group P suggest that Pumice achieved a smoother surface finish compared to the eggshell powder. This result implies that pumice (with lower Ra) may provide a more effective polishing outcome for PMMA materials.([Figure 9])

Discussion

This study evaluated the effectiveness of eggshell powder as a natural abrasive for polishing polymethyl methacrylate (PMMA) denture base resin, comparing its performance with that of commercially available pumice. While the findings indicate that eggshell powder has a slightly lower polishing efficiency than pumice, its performance was nevertheless notable, demonstrating potential as a viable alternative for surface finishing applications in prosthodontics.

Comparative polishing efficiency

The results indicated that while pumice generally produced a smoother surface, eggshell powder also achieved considerable polishing, making it a potential alternative.

Range of surface roughness values for pumice and eggshell powder

For specimens polished with pumice, the surface roughness (Ra) values ranged from a minimum of 0.47 µm to a maximum of 3.07 µm. In contrast, the specimens polished with eggshell powder had a surface roughness range from a minimum of 1.58 µm to a maximum of 4.62 µm. Although the overall average Ra value for eggshell was higher, the values were within an acceptable range for clinical applications.

Implications of surface roughness range

The observed range in Ra values for eggshell powder, although slightly broader than for pumice, indicates that eggshell powder can produce a similar surface smoothness under certain conditions. This suggests that refining factors such as particle size or adding surfactants may help to reduce variability and enhance the polishing efficiency of eggshell powder to align more closely with that of pumice.

Particle size and efficiency

The eggshell powder used in this study was prepared to a particle size of approximately 300 microns, which proved effective in reducing surface roughness but not as efficiently as pumice. Literature suggests that finer particle sizes can enhance abrasive potential, as smaller particles provide a more uniform and gentle polishing action. Future research could investigate grinding eggshell powder to a finer size to determine if this alteration significantly improves its polishing efficiency, potentially enabling it to match or even surpass the surface finishing capacity of pumice.

Eggshell powder as a natural substitute

The use of eggshell powder as an abrasive aligns with principles of sustainable and green dentistry. As a biodegradable, readily available, and renewable material, eggshell powder offers an environmentally friendly alternative to pumice, which is sourced from specific volcanic regions and is not renewable. Utilizing waste products like eggshells in clinical applications also contributes to waste reduction, making it an attractive option in eco-conscious dental practices. Given these benefits, eggshell powder could serve as a natural, accessible, and cost-effective abrasive, especially in regions where pumice may be costly or unavailable.

Potential additives to enhance polishing capacity

Surface-active compounds such as surfactants have been reported to improve the wettability and to enhance the mechanical properties of materials.[11], [12], [13] While this study used only eggshell powder and pumice, adding a surfactant like sodium lauryl sulfate could improve the wettability and even distribution of abrasive particles on PMMA surfaces. Future investigations might explore the inclusion of other additives, such as silica or various binding agents, which could potentially enhance the abrasive efficiency by improving the distribution of abrasive particles and increasing contact uniformity with the resin surface. Such modifications could increase the effectiveness of eggshell powder, making it a more competitive and efficient alternative to traditional abrasives. [14], [15]

Limitations of the study

The eggshell powder was prepared with a particle size of 300 microns. A finer particle size might provide a smoother finish and improve polishing efficiency. Further research should explore varying particle sizes to better understand the relationship between particle size and polishing outcomes.

Only PMMA acrylic resin was used in this study, so the results may not be applicable to other types of denture base materials, such as high-impact acrylics or flexible resins. Evaluating a broader range of materials would improve the generalizability of the findings.

Conclusion

Eggshell powder shows promise as a natural alternative to pumice for polishing denture base resins. While its current efficiency is slightly lower than pumice, adjusting its particle size and experimenting with additives may further improve its performance, aligning it with sustainable dentistry practices. Future research could focus on these modifications to optimize eggshell powder's efficiency and expand its application as a practical and eco-friendly abrasive in prosthodontic treatments.

Source of Funding

None.

Conflict of Interest

None.

References

- Al-Rifaiy M. The effect of mechanical and chemical polishing techniques on the surface roughness of heat-polymerized and visible light-polymerized acrylic denture base resins Author links open overlay panel. Saudi Dent J. 2010;22(1):13-7. [Google Scholar]

- . . . . [Google Scholar]

- Gungor H, Gundogdu M, Duymus Z. Investigation of the effect of different polishing techniques on the surface roughness of denture base and repair materials. J Prosthet Dent. 2014;112(5):1271-7. [Google Scholar]

- Srividya S, Nair C, Shetty J. Effect of different polishing agents on surface finish and hardness of denture base acrylic resins: a comparative study. Int J Prosthodont Restor Dent. 2011;1(11):7-11. [Google Scholar]

- Remond G, Nockolds C, Philips M. Implications of polishing techniques in quantitative x-ray microanalysis. J Res Natl Inst Stand Technol. 2002;107:639-62. [Google Scholar]

- Jefferies S. Abrasive finishing and polishing in restorative dentistry: A state of-art review. Dent Clin North Am. 2007;51(2):379-97. [Google Scholar]

- King’ori A. A review of the uses of poultry eggshells and shell membranes. Int J Poult Sci. 2011;10(11):908-12. [Google Scholar]

- Onwubu S, Mdluli P. Comparative Analysis of Abrasive Materials and Polishing System on the Surface Roughness of Heat-Polymerized Acrylic Resins. Eur J Dent. 2021;16(3):573-9. [Google Scholar]

- Onwubu S, Vahed A, Singh S, Kanny K. Reducing the surface roughness of dental acrylic resins by using an eggshell abrasive material. J Prosthet Dent. 2017;117(2):310-4. [Google Scholar]

- Song E, Kim D, Kim B, Lim J. Surface modification of CaCO3 nanoparticles by alkylbenzene sulfonic acid surfactant. Colloids Surf A Physicochem Eng Asp. 2014;461:1-10. [Google Scholar] [Crossref]

- Song E, DK, Lim J. Effect of adsorption of laureth sulfonic acid type anionic surfactant on the wetting property of CaCO3 substrate. J Ind Eng Chem. 2015;28:351-8. [Google Scholar] [Crossref]

- Tupinambá I, Giampá P, Rocha I, Lima E. Effect of different polishing methods on surface roughness of provisional prosthetic materials. J Indian Prosthodont Soc. 2018;18(2):96-101. [Google Scholar]

- Henuset Y. Abrasive materials from biological sources. . 2011. [Google Scholar]

- Taruna M, Sravya K, Avinash C, Jagini A, Jayyarapu D. Comparative evaluation of surface roughness of heat cure poly methylmethracylate resin using four different abrasives: An invitro study. Paripex - Indian J Res . 2021;10(9):32-4. [Google Scholar]

- O’brien W. Abrasion, Polishing, and Bleaching . Dental Materials and Their Selection. 2002. [Google Scholar]

- Abstract

- Introduction

- Materials and Methods

- Pumice powder

- Eggshell powder

- Preparation of polymethyl methacrylate (PMMA) specimens

- Polishing of the polymethyl methacrylate specimens

- Polishing procedure

- Results

- Discussion

- Comparative polishing efficiency

- Range of surface roughness values for pumice and eggshell powder

- Implications of surface roughness range

- Particle size and efficiency

- Eggshell powder as a natural substitute

- Potential additives to enhance polishing capacity

- Limitations of the study

- Conclusion

- Source of Funding

- Conflict of Interest

- References

How to Cite This Article

Vancouver

Vidhya BKD, Raj R, Veerakumar V, Bommiah D, Sekeran SB. Natural alternative for denture polishing - Eggshell powder [Internet]. IP Ann Prosthodont Restor Dent. 2025 [cited 2025 Sep 29];11(1):54-59. Available from: https://doi.org/10.18231/j.aprd.2025.011

APA

Vidhya, B. K. D., Raj, R., Veerakumar, V., Bommiah, D., Sekeran, S. B. (2025). Natural alternative for denture polishing - Eggshell powder. IP Ann Prosthodont Restor Dent, 11(1), 54-59. https://doi.org/10.18231/j.aprd.2025.011

MLA

Vidhya, Bhuvanesh Kumar Dharani, Raj, Raghavi, Veerakumar, Vignesh, Bommiah, Divyameena, Sekeran, Sajida Begum. "Natural alternative for denture polishing - Eggshell powder." IP Ann Prosthodont Restor Dent, vol. 11, no. 1, 2025, pp. 54-59. https://doi.org/10.18231/j.aprd.2025.011

Chicago

Vidhya, B. K. D., Raj, R., Veerakumar, V., Bommiah, D., Sekeran, S. B.. "Natural alternative for denture polishing - Eggshell powder." IP Ann Prosthodont Restor Dent 11, no. 1 (2025): 54-59. https://doi.org/10.18231/j.aprd.2025.011